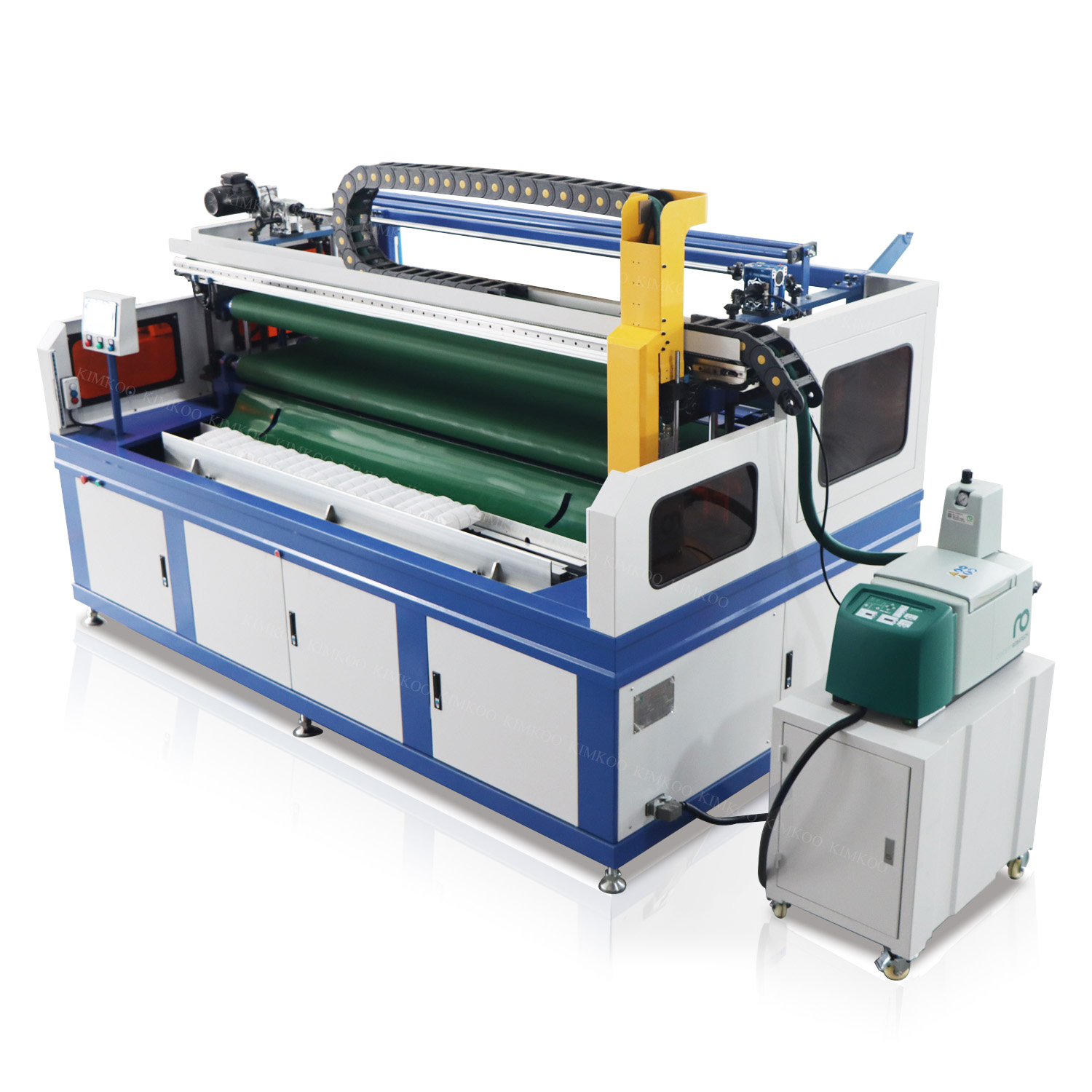

The semi-automatic pocket spring assembly machine is designed to assemble pocket spring units along with upper and lower non-woven covers. It extrudes glue onto the spring row through the nozzle to facilitate the assembly of the spring unit. Additionally, it offers the flexibility to choose whether upper and lower non-woven fabrics need to be bonded, catering to various production modes and requirements. In addition, this machine is typically paired with a pocket spring coiling machine to form a complete production line.

Featuring a user-friendly touch screen control panel, this machine is incredibly easy to operate, making it ideal for both seasoned professionals and newcomers to mattress manufacturing. Its high level of automation ensures stable performance, while the well-glued effect guarantees the quality of every mattress produced.

At the heart of this machine lies an imported PLC control system and servo technology, ensuring not only automation but also precise control over the glue-spraying process. Choose from top-of-the-line glue systems like USA Nordson or Switzerland Robatech for optimal performance.

This versatile machine can handle various types of pocket springs, whether drum type or cylindrical, and can assemble them in parallel or cellular forms. Thanks to intermittent glue spraying, it can reduce glue costs by over 40%. Additionally, you have the option to include adhesion of upper and lower non-woven cloth as needed.

But the benefits don’t stop there. Our Semi-Auto Pocket Spring Assembly Machine supports remote control for monitoring, online auto repair, program modification, and system updates, ensuring smooth operations and easy maintenance.

Features

- Assembly/glue efficiency of 6-8 rows per minute.

- Servo technology ensures precise mattress size.

- Four individually controlled glue nozzles for optimal glue distribution.

- Auto induction cutting functions streamline the process.

- Photoelectric safety protection ensures operator safety.

- Choose between continuous or intermittent gluing.

- Easy to operate and maintain, reducing downtime and increasing productivity.

- Invest in the Semi-Auto Pocket Spring Assembly Machine for seamless mattress production with unparalleled efficiency and quality control.

Technical Specification

| Model | JK-AS1 |

| Productivity | 7rows/s |

| Glue Box | USA Noordson/ Spain Merlot/ Robatect |

| Glue Spray | Spot spray or continuous spray |

| Girder | Servo drive |

| Demand of Gas Supply | 0.25m³ /min |

| Working Pressure | 0.5-0.6 mpa |

| Spring Placement Metthod | Manual placement |

| Total Power | 7KW |

| Input Voltage | 3AC380V |

| Frequency | 50/60 Hz |

| Weight | 2600 KG |

| Adhesive bed nets width | Maximum width of 2200 |

| Width of Non-Woven Fabric | 2300mm |

| Thickness of non-woven fabric | 50-100g/ m² |

| Spring height | 60-300mm |

| Size Lenght | length3.8m, Width 1.8m, Height 2m |

Tip: ZIMLIN Mattress Machinery